MES Evolved

All-in-One MES, WMS & Track & Trace Software

Affordable, tailored solution for real-time job, material, and asset tracking across manufacturing plants, warehouses, and field sites.

Features: WIP Tracking, Inventory Management, Materials Traceability, RFID, and Job Tracking.

Advanced WIP Tracking Solutions

BellHawk’s real-time WIP Tracking enhances efficiency across the board with real-time tracking and automation, reducing errors and costs while ensuring control over materials and goods.

Streamlined Warehouse Operations with Inventory/Asset Tracking

Optimize operations with real-time inventory tracking, enhancing shipping, receiving, and order fulfillment. Using barcode scanning and RFID, it reduces errors and boosts efficiency across all industries.

Precision RFID Inventory Systems

Our RFID tracking software enhances material tracking with real-time visibility and compliance support, reducing errors and boosting efficiency using contactless technology.

Track & Trace Materials Instantly

Our traceability solutions meet GS1, FDA, and CFR 21 Part 11 standards with real-time tracking, detailed audit trails, and seamless integrations, reducing compliance risks and costs.

Strategic Production Planning

Our solutions optimize manufacturing operations by providing real-time visibility into inventory, job tracking, and materials flow. This enables teams to improve efficiency, maintain accuracy, prevent production delays, and reduce operational costs across every stage of the process.

Redefining Boundaries Across Industries

Our expertise spans across manufacturing industries like food and beverage, pharmaceutical, and industrial supply chains, offering personalized service to help mid-sized organizations track operations with precision.

Manufacturing Industry

Gain real-time visibility into jobs, raw materials, and finished goods to reduce errors, delays, and downtime on the shop floor.

Industrial Distribution Industry

Track every item from receiving to shipping with barcode and RFID scanning for streamlined inventory control and accurate order fulfillment.

Medical Supplies Industry

Ensure compliance and traceability with real-time tracking of medical devices, PPE, and test materials across labs and warehouses.

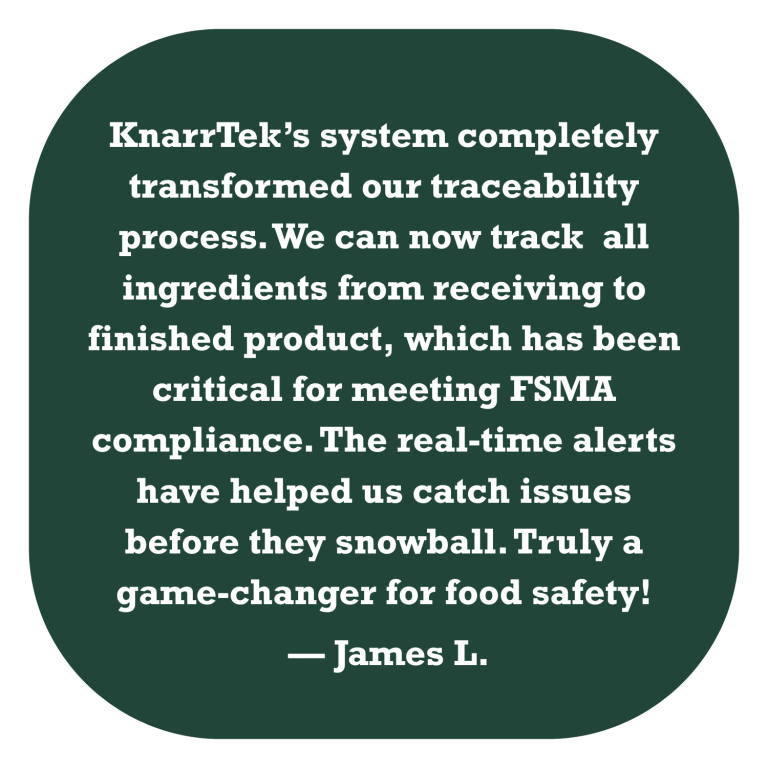

Food and Beverage Industry

Track ingredients, WIP, and finished goods through every step to ensure food safety, accelerate recalls, and meet regulatory compliance.

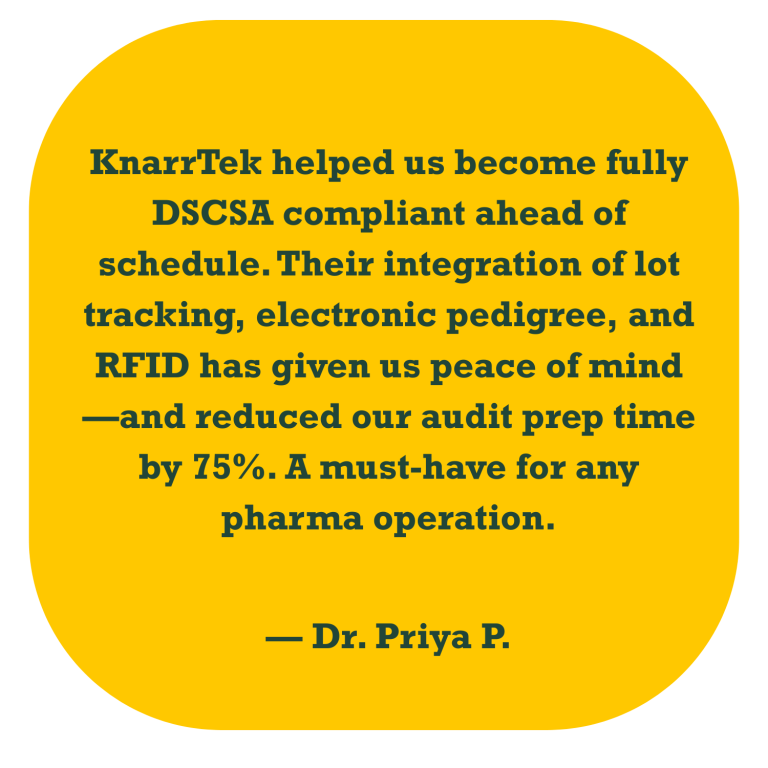

Pharmaceutical Industry

Meet DSCSA, CFR 21 Part 11, and other FDA standards with real-time tracking, digital audit trails, and seamless data collection.

Results That Speak for Themselves

Remarkable Numbers Throughout

95% Great Ratings Over the Years

90%

works out of box

6-8K

savings per month

1-3

month implementation