|

Software + Services + Expertise |

|

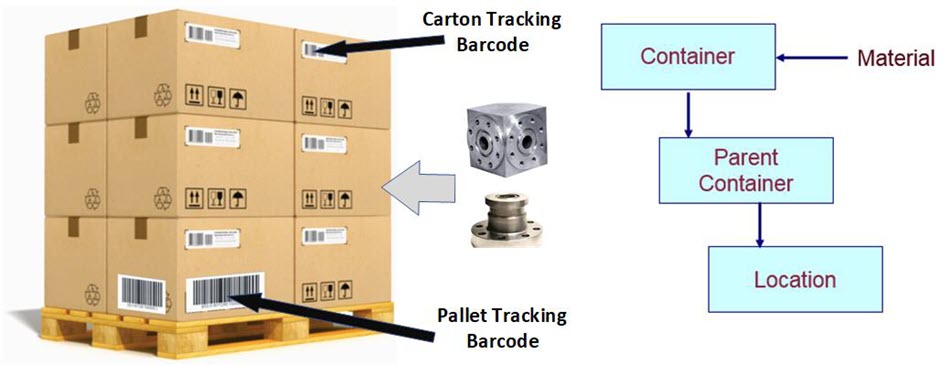

An important aspect of work-in-process tracking is the ability to track totes, pallets, and carts which contain multiple different parts.

WIPtracker/BellHawk can track nested containers, with each container in the containers table having a parent container. This enables BellHawk to track multiple different WIP materials in a container, such as a tote or box, and to track multiple boxes on a pallet or multiple totes on a cart. This then enables tracking movement of the parent container, and all its child containers, using a single barcode or RFID scan of the parent container barcode or RFID tag.

Another capability that makes WIPtracker/BellHawk unique is the ability to track WIP parts without creating special part numbers for each WIP material stage that a product goes through in its transformation from raw materials to finished products.

Here, BellHawk uses the finished product part number but adds a WIP flag to indicate that this is not a finished product and also tracks which operation/route step was used to make the WIP materials.

This enables recording WIP out from an operation in a route, without needing to create a special part number. Here the container is marked a containing WIP materials with a record of the operation/route step that produced it. If a subsequent job uses the same WIP materials, then the left over WIP materials can be assigned to the new job, just like any other inventory.

Please click here to return to an Overview of WIPtracker.

| About KnarrTek | Technology |

|

Services | Cost Savings |

| Copyright © KnarrTek Inc. 2024 |

| Technology |

|

Services |

| About KnarrTek | Copyright © KnarrTek Inc. 2024 | Cost Savings |