|

Software + Services + Expertise |

|

Many of us have experienced a situation similar to this: We make a range of products that use a common component, a "widget", that we make in house. There are 12 widgets in stock. The manager of department A wants to run a job requiring 6 widgets and the manager of department B wants to run a job requiring 8 widgets.

Both look into their inventory tracking or ERP system and see that there are 12 widgets in stock, so they both issue work orders to make their respective products.

An employee of department A then goes to the stock room and withdraws the 6 widgets needed for their job. As a result, when an employee from department B goes to the stock room, they find that there are only 6 widgets left, instead of the 8 they need, and we have a stock-out that disrupts production until it is resolved.

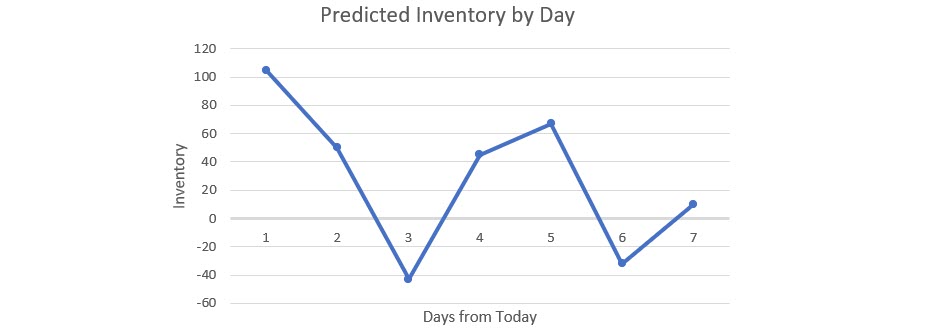

In this white paper, we look at how to avoid this situation using lean inventory prediction.

To download a PDF of the white paper, please click on:

| About KnarrTek | Technology |

|

Services | Cost Savings |

| Copyright © KnarrTek Inc. 2024 |

| Technology |

|

Services |

| About KnarrTek | Copyright © KnarrTek Inc. 2024 | Cost Savings |