|

Software + Services + Expertise |

|

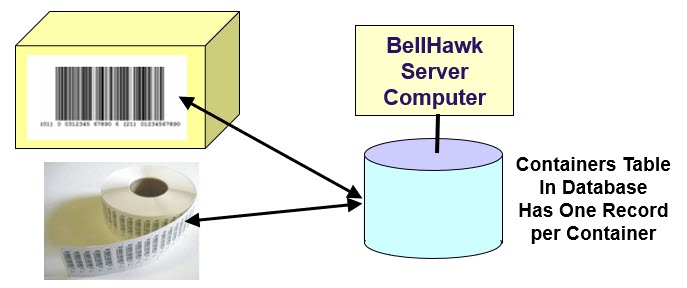

BITS performs container-based tracking, in which a unique tracking barcode is placed on each container of materials, individual item, or asset that needs to be tracked. This barcode is then scanned whenever materials are received, added to or removed from a container, moved to a new location or shipped to a customer.

This is the same method used by organizations such as FedEx, UPS and Amazon but extended to tracking inventory within multiple warehouses, stock rooms, manufacturing facilities, as well as outdoors in yards and at building sites.

These tracking barcodes can come from preprinted rolls of serialized barcodes, such as that shown here, or users can provide their own unique tracking barcodes. Please note that UPC codes, commonly attached to product boxes, only identify the product and not each unique box or other container.

Each tracking barcode is used to reference an entry in the Containers table in the BellHawk database, which contains information such as Part Number, Location, Quantity, Lot Number and Serial Number, as well as user defined parameters, such as size and color.

When each container of materials is received, a unique tracking barcode is attached to the container and the part number and quantity of parts inside the container recorded, as well as possibly lot and serial numbers, as well as any user defined parameters.

BITS runs on a computer that is shared by multiple small companies. For barcode scanning performance reasons, each client company, using BITS, is limited to no more than 5,000 active entries in the containers table.

If users exceed this limit, then it is necessary to move their private BellHawk website and database to a dedicated computer located in their warehouse or data center. Please see separate data sheet on running BellHawk in a dedicated Windows computer.

Such a move to a dedicated processor also enables capabilities such as warehouse management, barcode label printing, RFID container tracking, and integration with ERP or accounting systems to be added to BellHawk.

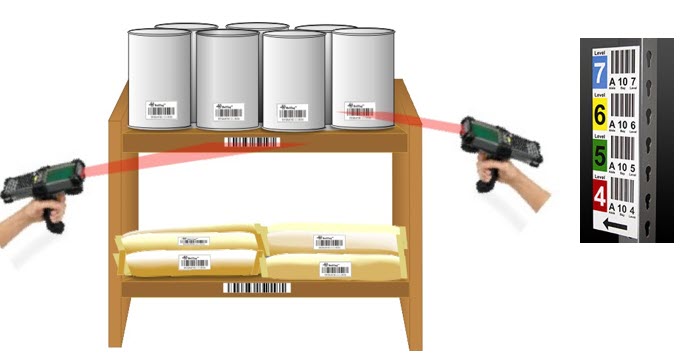

The location of each container is then recorded by scanning a unique location barcode attached to each shelf, rack or floor location marker, followed by scanning the unique tracking barcode placed on each container moved to that container.

This enables clients to track the location of each container, asset, or uniquely serialized item in real-time, until it is shipped, when the tracking barcode is scanned again. It also enables containers with the same part number to be simultaneously tracked at multiple different locations.

Please click here to return to an Overview of BITS.

| About KnarrTek | Technology |

|

Services | Cost Savings |

| Copyright © KnarrTek Inc. 2024 |

| Technology |

|

Services |

| About KnarrTek | Copyright © KnarrTek Inc. 2024 | Cost Savings |